Our Wear Abrasion Resistant Steel Plates such as NM400, NM500, XAR 450, AR200, AR400, AR600, AR300, AR450, AR550, and AR500 offer superior strength and resistance to wear and tear. These plates are designed to withstand harsh conditions and heavy abrasive environments, making them ideal for industries that require high durability and resistance to abrasion. Manufactured from high-quality carbon steel, these plates are commonly used in mining, construction, material handling, and heavy machinery. NM400 / NM500 Wear Steel Plate: Known for their outstanding wear resistance, NM400 and NM500 are suitable for applications where long-term durability under abrasive conditions is essential. NM500 offers superior hardness and abrasion resistance compared to NM400, making it ideal for more severe conditions. XAR 450 Steel Plate: A high-strength abrasion-resistant steel, XAR 450 provides excellent wear resistance and is used in industries where superior hardness is required to combat heavy abrasi

Key Features:

Applications:

Abrasion resistant steel plate is also known in the engineering industry by a variety of other nadmes which include:

Wear resistant plate

Wear plate

400 Brinell plate

NM400, NM450 and NM500 plate are abrasion resistant quenched and tempered alloy steels. This grade of alloy steel exhibits high abrasion resistance and hardness. The addition of carbon and manganese coupled with quenching and tempering increase the hardness of the steel and create a durable, impact-resistant surface. However, as hardness increases, formability and the ability to easily machine and weld the alloy decrease. Special machining processes are needed to prevent work hardening and chipping during manufacturing.

| Item | Wear Abrasion Resistant Steel Plate / Abrasion Resistant Steel Sheet |

| Grade | NM400, NM500 |

| Thickness | 4mm - 100mm |

| Size |

Width:1000mm - 2500mm Length: 3000mm - 8000mm Can be customized |

| Item | C | Si | Mn | P | S | Cr | Ni | Mo | Bt |

| NM500 | ≤0.29 | ≤0.70 | ≤1.60 | ≤0.025 | ≤0.010 | ≤1.00 | ≤1.00 | ≤0.60 | ≤0.0004 |

|

Tensile Strength |

Elongation |

-40°C Impact Resistance |

Initial Hardness(HB) |

Hardness (HB) |

|

≥1400MPa |

≥10% |

ak≥30(J) |

450-540 |

≥500 |

NM400 and NM450 are multi-purpose wear plates. Due to its high toughness, good bending and welding performance, it can also be used for load applications in some applications.

NM500 is a bendable and welded wear plate that can be used in areas where wear resistance is required.

NM550 is an average hardness of 550HBW wear-resistant steel plate, its toughness and NM500 the same, is used in high wear and tear occasions. It is mainly for users and manufacturers of wear-resistant steel plates using high manganese steel castings or Brinell hardness of 500. When upgrading from the NM500 steel sheet to the product, the Brinell hardness increased by 50 units, without loss of steel toughness in the case of extended wear life.

NM600 is the world's hardest wear-resistant steel plate, the hardness value of 600HBW. It is generally used in situations where wear is extremely severe and is mainly used to replace cast steel, chrome cast iron, and surface hardened metals. Despite its high hardness, we are still able to machine, weld and cut it. Although the hardness of the NM600 is very high, it still has a very high impact toughness.

We TJYCT STEEL always provide Reliable Quality, Fast Delivery, Competitive Price to our clients.Honest people, Warm-hearted service is our obligation! Contact with us and establish long termwin - win relationships between us!

TJYCT STEEL CO., LTD is a comprehensive company, who is founded in 2008. Specialized in stainless steel products, seamless steel pipe, welded steel pipe,steel coil and plates. It is located in Tianjin, the Steel base of China, which is known all over the world. It is very close to Xingang Seaport, where is much convenient in land carriage,carriage by sea and carriage by air.

"Providing Quality Products, Excellent Service, Competitive Prices and Prompt Delivery" we are looking forward to even greater cooperation with overseas customers based on mutual benefits.

We warmly welcome friends from all over the world come and cooperate with us.

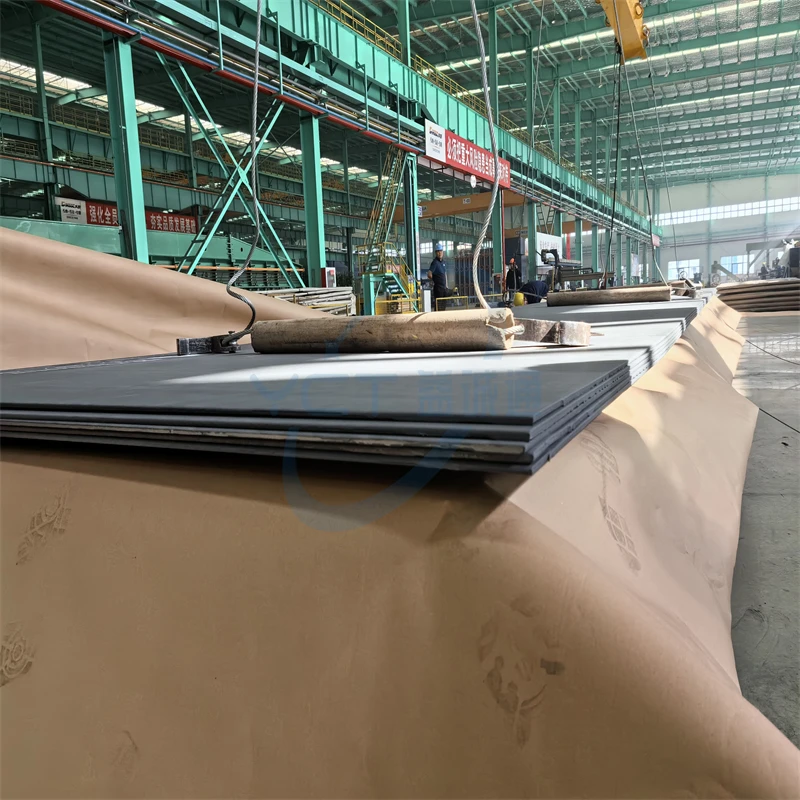

Wear resistant steel plate packing and shipping

| Package |

Standard export seaworthy package,suit for all kinds of transport, or as required. |

|

| Bulk Size | Any size | |

| Price term | Ex-Work,FOB,CNF,CFR,CIF,etc | |

| Payment | T/T, LC | |

| Loading Port | Tianjin, Xingang Port, Shanghai, Qingdao, Ningbo... any China seaport | |

| Container |

1*20ft container load Max. 26 Ton, Max. length 5.8m 1*40ft container load Max. 26 Ton, Max. Length 11.8m |

|

More Products you maybe interested pls contact us freely

Our team

*Reply your inquiry within 24 hours

*Customized design is available,Third Party Inspection is welcomed

*Delivery the goods to our customer all over the world with speed and precision